In the United States, developers are planning a significant expansion of hydrogen production using electricity-based technologies.

This shift could signal a move away from the current reliance on hydrocarbon feedstocks. Planned electrolyzer installations, which produce hydrogen from water using electricity, could increase U.S. capacity from 116 megawatts (MW) to 4,524 MW, according to the Department of Energy’s Hydrogen Program Record. If realized, this expansion could result in an annual hydrogen production of approximately 0.72 million metric tons (MMmt) through electrolysis.

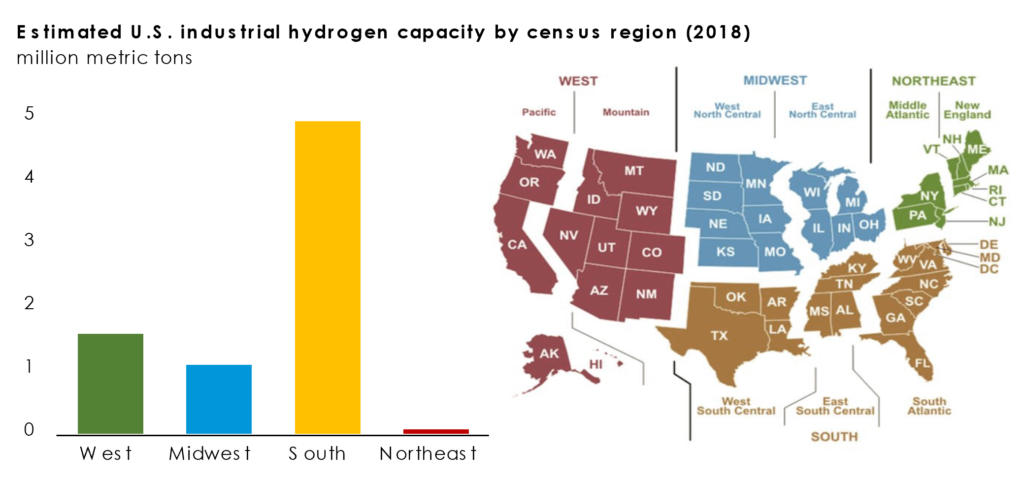

This output would supplement the current 10 MMmt of hydrogen produced from fossil fuels and industrial byproducts. Notably, electrolyzers meeting low-carbon intensity standards may qualify for a production tax credit if construction begins by 2033.

Hydrogen’s Vital Role in Industries and Energy

Hydrogen plays a crucial role in various sectors, including petroleum refining and fertilizer production. It also serves as a storable fuel for electricity generation, either in hydrogen gas turbines or blended with natural gas in traditional turbines.

Currently, steam methane reforming (SMR) or other industrial processes derive almost all of the 10 MMmt of hydrogen produced annually in the U.S.

The U.S. Energy Information Administration (EIA) is developing a new hydrogen supply model and refining consumption models to incorporate hydrogen projections in its Annual Energy Outlook for 2025. A working group discussion with stakeholders will take place on June 12, 2024.

Electrolyzers vs. Steam Methane Reforming (SMR): A Comparison

Electrolyzers produce hydrogen through electrolysis, a process that splits water using electricity, with oxygen as the sole byproduct.

In contrast, SMRs use hydrocarbons as feedstock, resulting in carbon monoxide and carbon dioxide byproducts that require capture and sequestration for net-zero emissions. Hydrogen produced by electrolyzers powered by renewable energy is considered carbon-neutral.

Advancements in Electrolyzer Technologies

The International Energy Agency (IEA) reports that two types of electrolyzer technologies are currently commercially deployed: Proton Exchange Membrane (PEM) and Alkaline.

Both technologies require further advancements to remain competitive and differ in construction cost, start-up times, and materials used. Regardless of the materials, electrolyzers can utilize electricity generated from renewable resources.

Current Landscape and Future Potential

While several electrolyzer projects are in the pipeline, SMR technology still produces most commercially consumed hydrogen in the U.S.

The SMR process involves applying high-temperature steam to methane and a catalyst to produce hydrogen, carbon monoxide, and carbon dioxide.

However, operators can equip SMR units with carbon capture and storage (CCS) capabilities to reduce the carbon footprint by storing carbon dioxide underground.

This technology has been successfully implemented at the Coffeyville Resources Nitrogen Fertilizers plant in Oklahoma since 2013. This shift towards electricity-based hydrogen production marks a potential turning point in the industry, offering a more sustainable pathway for meeting the growing demand for this versatile energy carrier.